Hi, welcome to the next blog post. Today, we will discuss the cost of terrace waterproofing treatment. Most clients ask what the waterproofing cost is for a damaged terrace.

Before we know this cost, we need to know what work needs to be done on that roof and what materials are needed. Only then will it be easy for us to calculate the cost. We also need to know how many workers are needed to do the work and how many days the work will take.

So first of all, we list out what work needs to be done and what materials should be collected. The following is the list of materials and work for the treatment of a damaged terrace.

Working List

- Dismantling

- Surface Cleaning

- Waterproofing Chemical Coating

- Application of Polymer Modified Mortar (PMM)

- Chemical Thin Coating

- Application of Waterproofing Membrane Sheet

- Plain Cement Concrete

- Tiling

Required Material & Machine List

- Cement

- Sand

- Chips

- Tiles

- Chemicals (latex, sheet glue)

- Membrane Sheet

- Sand Filter Net

- Dismantle Machine

- Jawel (trowel)

- Planesheet

Understanding Terrace Waterproofing

Terrace waterproofing is a critical process to protect your building from water damage. Especially in regions with heavy rainfall or extreme weather conditions. In both old and new buildings, a damaged terrace can lead to leaks, structural weakening, and even health hazards like mold growth.

Waterproofing not only extends the lifespan of your terrace but also enhances the overall durability of the building.

However, the cost of waterproofing depends on multiple factors, including the extent of damage, the size of the terrace, the materials used, labor charges, and regional pricing variations.

In this blog post, we’ll break down individual steps of the waterproofing process, estimate the costs involved, and provide insights into how you can plan and budget for this essential home maintenance task.

Step-by-Step Breakdown of the Waterproofing Process

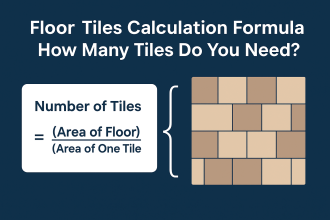

1. Dismantling

The first step in waterproofing a damaged terrace is dismantling the existing surface. This involves removing old tiles, PCC, screed, or any damaged material up to the base concrete slab. Dismantling is labor-intensive and requires tools like dismantling machines and trowels. Depending on the terrace’s condition, this step can take 1-4 days for a medium-sized terrace (500-1000 square feet).

Cost Factors:

- Labor: 2-4 workers, depending on the terrace size.

- Equipment: Rental or purchase of dismantling machines.

- Debris Removal: Disposal of old tiles and materials may incur additional costs.

2. Surface Cleaning

Once the old surface is removed, the terrace must be thoroughly cleaned to remove dust, debris, and loose particles. This ensures proper adhesion of waterproofing materials. Surface cleaning may involve manual sweeping, pressure washing.

Cost Factors:

- Labor: 1-2 workers for cleaning.

- Equipment: Pressure washers or cleaning tools.

- Time: Usually completed in 1 day.

3. Waterproofing Chemical Coating

A waterproofing chemical coating, such as a liquid-applied membrane or latex-based sealant, is applied to the cleaned surface. This creates a primary barrier against water seepage. The coating must be applied evenly, often in multiple layers, to ensure complete coverage.

Cost Factors:

- Materials: Waterproofing chemicals (e.g., latex-based sealants) cost [Rs 35- Rs 50] per square foot, depending on the brand and quality.

- Labor: Skilled workers are needed to ensure proper application.

- Coverage: A 500-square-foot terrace may require 5-10 Liters of chemical coating.

4. Application of Polymer Modified Mortar (PMM)

Polymer Modified Mortar (PMM) is a cement-based mixture enhanced with polymers to improve adhesion and flexibility. It is applied over the chemical coating to provide additional strength and waterproofing. PMM is particularly effective in filling cracks and leveling the surface. It is mandatory to fill in the joint of the Slab and the Brick wall to connect each other.

Cost Factors:

- Materials: Cement, sand, and polymer additives. PMM costs approximately Rs 50- Rs 70 per square foot.

- Labor: Requires skilled masons for proper mixing and application.

- Time: 1-2 days, depending on the terrace size and complexity.

5. Chemical Thin Coating

A second layer of chemical coating, often thinner than the first. It is applied to enhance the durability of the waterproofing system. This layer seals any minor imperfections in the PMM layer and prepares the surface for the membrane sheet.

Cost Factors:

- Materials: Similar to the first chemical coating, costing [Rs 35- Rs 50] per square foot.

- Labor: Minimal additional labor, as this can often be done by the same team applying the PMM.

6. Application of Waterproofing Membrane Sheet

Waterproofing membrane sheets, such as bituminous or PVC membranes, are laid over the coated surface. These sheets provide a robust barrier against water and are particularly effective for terraces exposed to heavy rainfall. The sheets are glued using sheet glue or heat-sealed, depending on the material.

Cost Factors:

- Materials: Membrane sheets cost Rs 110- Rs 160 per square foot, depending on thickness and quality.

- Labor: Requires skilled technicians for precise installation.

- Time: 1-2 days for a 500 square feet terrace.

7. Plain Cement Concrete (PCC)

A layer of Plain Cement Concrete (PCC) is applied over the membrane to protect it from physical damage and provide a smooth base for tiling. PCC is a mixture of cement, sand, and chips (aggregate), typically applied in a 2-2.5-inch-thick layer.

Cost Factors:

- Materials: Cement (Rs 900 per bag), sand (Rs 10000 per tip), and chips (Rs 10000 per tip).

- Labor: 2-3 workers for mixing and laying the concrete.

- Time: 1-2 days, with a curing time of 7-14 days before tiling.

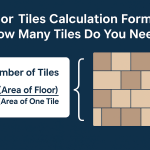

8. Tiling

The final step is tiling the terrace with weather-resistant tiles. Tiles not only enhance the aesthetic appeal but also add an extra layer of protection. The choice of tiles (ceramic, porcelain, or anti-slip) significantly affects the cost. The main thing is the tile gap. It should maintain a 2 mm – 3 mm gap between every tile.

Cost Factors:

- Materials: Tiles range from Rs 150 to Rs 500 per square foot, depending on quality and design.

- Labor: Skilled tilers are needed for precise installation.

- Time: 2-3 days for a 500 square foot terrace.

Cost Estimation for Terrace Waterproofing

To provide a realistic cost estimate, let’s assume a 500-square-foot terrace as a baseline. Costs will vary depending on location, labor rates, and material quality, but here’s a detailed breakdown:

Material Costs

| Item | Quantity | Cost per Unit | Total Cost |

|---|---|---|---|

| Cement | 25 bags (50 kg each) | 850-950 per bag | 21000-24000 |

| Sand | 2 tip | 9000-10000 per tip | 18000-20000 |

| Chips | 1 tip | 9000-10000 per tip | 9000-10000 |

| Tiles | 500 sq.ft. | 150 per sq ft. | 75000-85000 |

| Waterproofing Chemicals | 10 liter | 850-1000 per liter | 8500-10000 |

| Membrane Sheet | 500 sq.ft. | 60-100 per sq ft. | 30000-50000 |

| Sheet Glue | 2 Kg | 1400-1600 per kg | 2800-3200 |

| Sand Filter Net | 2 meter | 140-160 per meter | 280-320 |

| Total Material Cost | 164000-202520 |

Labor Costs

| Task | Workers | Days | Cost per Worker/Day | Total Cost |

|---|---|---|---|---|

| Dismantling | 3 | 2 | 1500-2000 | 4500-6000 |

| Surface Cleaning | 2 | 1 | 1500-2000 | 3000-4000 |

| Chemical Coating | 2 | 1 | 1400-1800 | 2800-3600 |

| PMM Application | 2 | 2 | 2000-2200 | 4000-4400 |

| Chemical Thin Coating | 2 | 1 | 1400-1800 | 2800-3600 |

| Membrane Sheet Installation | 2 | 2 | 2000-2500 | 4000-5000 |

| PCC Application | 3 | 2 | 2000-2500 | 6000-7500 |

| Tiling | 3 | 3 | 2200-2500 | 6600-75000 |

| Total Labor Cost | Rs33300-41600 |

Equipment Costs

| Item | Cost |

|---|---|

| Dismantle Machine Rental | 1500-2500 per day |

| Pressure Washer Rental | 1500-2000 per day |

| Total Equipment Cost | 3000-4500 |

Total Estimated Cost

| Category | Cost Range |

|---|---|

| Materials | 164000-202520 |

| Labor | 33300-41600 |

| Equipment | 3000-4500 |

| Total | 200300-248620 |

For a 500-square-foot terrace, the total cost of waterproofing typically ranges from Rs 200300- Rs 248620. This equates to 400 to 497 per square foot. Larger terraces or those with severe damage may cost more, while smaller or less damaged terraces may cost less.

Factors Affecting Waterproofing Costs

Several factors influence the cost of terrace waterproofing:

- Terrace Size: The Size of the terrace is directly proportional to the Cost.

- Extent of Damage: Severely damaged terraces may need additional repairs, such as crack filling or structural reinforcement.

- Material Quality: Premium tiles, high-quality membrane sheets, or branded waterproofing chemicals cost more but offer better durability.

- Labor Rates: Labor costs vary by region. Urban areas with higher living costs typically have higher labor rates.

- Accessibility: Terraces that are difficult to access may require additional equipment or time, increasing costs.

- Weather Conditions: Work during rainy seasons may require protective measures like planesheets, adding to the cost.

Tips for Cost Optimization

- Compare Quotes: Get quotes from multiple contractors to ensure competitive pricing.

- Choose Durable Materials: Investing in high-quality materials can reduce long-term maintenance costs.

- Plan During Off-Season: Scheduling work during dry seasons or off-peak times may reduce labor and equipment costs.

- Regular Maintenance: Regular inspections and minor repairs can prevent extensive damage, reducing the need for full waterproofing.

- DIY Cleaning: If feasible, handle surface cleaning yourself to save on labor costs.

Additional Considerations

- Warranty: Choose materials and contractors that offer warranties (typically 2-5 years) for waterproofing work.

- Permits: Check if local regulations require permits for terrace renovations.

- Safety: Ensure workers follow safety protocols, especially when dismantling machines or working at heights.

- Post-Waterproofing Care: Avoid heavy foot traffic or placing heavy objects on the terrace during the curing period (7-14 days).

Conclusion

Terrace waterproofing is crucial to protect your home from water damage and maintain its structural integrity. By understanding the steps involved—dismantling, surface cleaning, chemical coating, PMM application, membrane installation, PCC, and tiling—you can better plan and budget for the project.

By choosing reliable contractors, high-quality materials, and proper maintenance, you can ensure a leak-free terrace that enhances your home’s value and comfort. If you’re planning to waterproof your terrace, start by assessing the damage, gathering quotes, and preparing a detailed budget. A well-executed waterproofing project will save you from costly repairs in the future and provide peace of mind during heavy rains.

![Calculate a Approximate Construction Cost of the 3 Storey Building[Nepal] approximate construction cost](https://techmeengineer.com/wp-content/uploads/2025/05/piclumen-1746761432208-150x150.png)

![🏡 How to Build a Strong House in Nepal: Why Most Homes Fail and What You Should Do Instead [5 Reason] build a strong house in Nepal](https://techmeengineer.com/wp-content/uploads/2025/07/WhatsApp-Image-2025-07-02-at-07.01.45_7560519f-330x220.jpg)

![Calculate a Approximate Construction Cost of the 3 Storey Building[Nepal] approximate construction cost](https://techmeengineer.com/wp-content/uploads/2025/05/piclumen-1746761432208-330x220.png)