“The strength of a structure lies not only in the materials used but in how carefully they are handled.”

Why Honeycomb in the RCC Structure Matters?

Honeycomb in RCC structure is one of the most common yet critical defects observed in modern concrete construction. Despite using high-quality materials, many buildings in Nepal and around the world suffer from premature deterioration because of concrete honeycombing.

These seemingly small cavities can compromise structural integrity, safety, and long-term durability.

In this in-depth article, we’ll uncover:

- What is honeycombing?

- How to detect it early

- What causes it

- Its real-world impact on buildings

- Proven solutions and preventive strategies

This guide is especially useful for civil engineers, site supervisors, architects, contractors, and homeowners who are serious about quality in RCC construction.

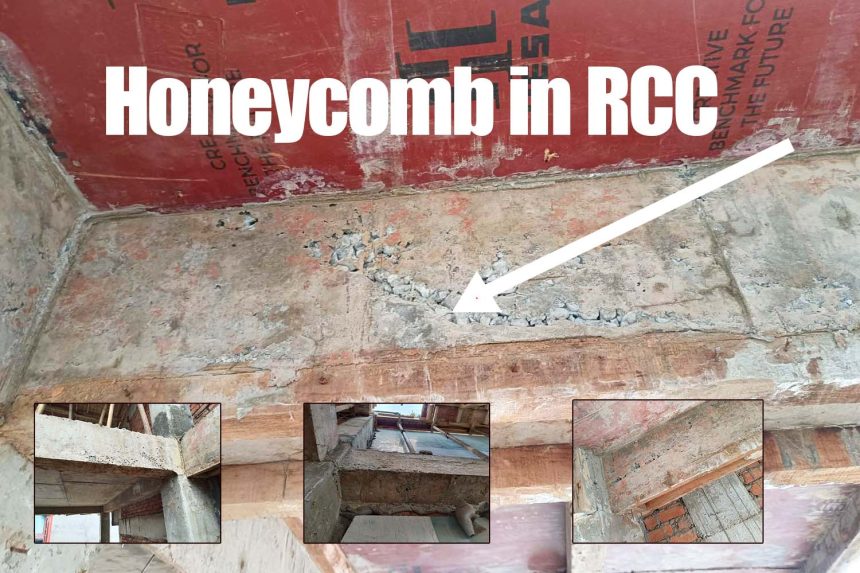

What is Honeycomb in RCC Structure?

Honeycomb in RCC structure refers to voids or hollow pockets formed within the concrete surface or internal body due to improper compaction or poor workmanship during casting. These pockets look like the patterns found in a natural honeycomb—hence the name.

These defects mostly occur in:

- Columns

- Beams

- Slabs

- Retaining walls

- Foundations

Concrete honeycombing not only affects aesthetics but also reduces load-bearing capacity and durability of RCC elements.

Real Case Scenario from Nepal

A 5-storey residential building in Kathmandu’s Tokha area was recently diagnosed with significant honeycombing in its ground-floor columns. The building, just 3 years old, started showing diagonal cracks and water leakage during the monsoon. Upon inspection, engineers found RCC construction defects linked to poor compaction in RCC and inadequate vibration during concreting.

Rectification cost: NPR 8 lakhs (~USD 6,000), which could have been avoided.

Common Causes of Honeycomb in RCC Structure

Let’s explore the 7 major causes that lead to honeycombing:

- Poor Compaction in RCC

Improper vibration during concreting is the #1 reason. Without proper vibration, trapped air remains in concrete, forming voids. - Improper Concrete Mix Design

Using low cement content, poor gradation of aggregates, or dry mixes makes concrete difficult to flow and fill formwork properly. - Congested Reinforcement

When reinforcement bars are too dense, concrete cannot flow around them, especially without mechanical vibration, resulting in concrete honeycombing. - Inadequate Formwork Sealing

Gaps in shuttering allow cement paste to escape, leaving behind only coarse aggregates, creating a honeycomb in the RCC structure. - Delayed Concrete Placement

Delays after mixing or using concrete that has already started to set can prevent it from compacting well. - Lack of Skilled Manpower

Untrained laborers often ignore vibration during concreting or don’t understand mix behavior, causing RCC construction defects. - Harsh Weather Conditions

High temperatures or strong winds during casting can lead to moisture loss, resulting in poor finishing and surface honeycombing.

How to Identify Concrete Honeycombing?

Here are the top 5 signs you should look out for:

- Visible voids or gaps on column or beam surfaces

- Coarse aggregates are seen on the outer layers without sufficient mortar

- Water seepage through concrete elements

- Sound differences when tapping with a hammer (hollow vs solid sound)

- Surface discoloration and flaking over time

- Early identification helps prevent long-term RCC construction defects.

|  |

|  |

Effect of Honeycomb in RCC Structure

Honeycombing can severely reduce:

| Effect | Impact on RCC Structure |

|---|---|

| Structural Strength | Reduces load capacity by 10–30% |

| Durability | Moisture penetration leads to corrosion |

| Seismic Resistance | Weak zones can fail during earthquakes |

| Aesthetics | Unfinished, patchy surface appearance |

| Maintenance Cost | Higher due to waterproofing, repair, etc. |

Note: Ignoring concrete honeycombing is an expensive mistake.

How to Fix Honeycomb in RCC Structure: Repair Techniques

Depending on severity, here are the top 4 repair solutions:

- Pressure Grouting in Concrete

- Injecting grout (cement + chemicals) under pressure

- Fills internal voids effectively

- Best for deep honeycombing

- Surface Patching

- Chiseling loose particles

- Applying repair mortar

- Suitable for superficial honeycombing

- Epoxy Injection

- Low-viscosity epoxy injected into cracks or voids

- Restores structural strength

- More expensive but durable

- Micro Concrete Jacketing

- Recasting portion with high-strength micro concrete

- Best for severely damaged beams or columns

Note: Always test repaired area using rebound hammer or ultrasonic pulse velocity to ensure quality.

Preventive Measures to Avoid Honeycomb in RCC Structure

Prevention is better than repair

Here are 9 smart tips to prevent honeycombing in concrete:

- Use a well-designed concrete mix with proper workability (slump 75–100 mm for RCC).

- Ensure adequate vibration during concreting—use needle vibrators properly.

- Avoid cold joints by placing concrete continuously.

- Seal all joints and gaps in shuttering before casting.

- Use proper spacing between reinforcement bars.

- Never add water at the site to increase workability.

- Cast concrete in layers, not full depth at once.

- Hire trained workers and monitor compaction techniques.

- Avoid casting during extreme heat or rain.

IS Code and Standards for Honeycombing

According to IS 456:2000 (Clause 11.2), surface defects like honeycombing must be inspected and treated before further construction proceeds. IS 516 and IS 1199 also outline testing and quality control for concrete.

Grouting in Concrete: A Game-Changer

Grouting in concrete is becoming a go-to solution in Nepal for internal honeycombing and void filling. High-pressure grouting with non-shrink compounds such as Sika Grout or Fosroc Conbextra GP ensures:

- Long-lasting repair

- High bond strength

- Seepage resistance

Always follow manufacturer guidelines and use skilled technicians.

Data Table: Honeycomb Tolerance and Risk Level

| Honeycomb Depth (mm) | Risk Level | Recommended Action |

|---|---|---|

| <10 mm | Low | Patch repair |

| 10–25 mm | Moderate | Grouting or patching |

| 25 mm or deep | voids High | Grouting + Structural check |

Myths and Misconceptions

Myth 1: “Honeycomb is just cosmetic.”

Fact: It’s a sign of internal voids and poor bonding.

Myth 2: “Extra cement will solve honeycombing.”

Fact: Over-cementing increases shrinkage, not strength.

Myth 3: “Surface repair is enough.”

Fact: Deep honeycombing requires grouting in concrete or even recasting.

Conclusion: Strength Lies in Details

Honeycomb in RCC structure is not just a minor defect—it’s a red flag. If left unchecked, it can lead to structural failure, water leakage, and financial losses. But with the right knowledge, skilled manpower, and quality control, concrete honeycombing can be prevented and corrected.

Investing in proper vibration during concreting, high-quality grouting in concrete, and field supervision is cheaper than dealing with future damages.

![🏡 How to Build a Strong House in Nepal: Why Most Homes Fail and What You Should Do Instead [5 Reason] build a strong house in Nepal](https://techmeengineer.com/wp-content/uploads/2025/07/WhatsApp-Image-2025-07-02-at-07.01.45_7560519f-330x220.jpg)